Orbital Sanders vs Sheet Sanders: The Differences

Do you ever feel like wood sanding is tedious and time-consuming? You are not alone. Professionals and DIYers like you feel the same way. You want to catch up with your favourite club’s soccer game, but you know the amount of work glaring at you will make you miss the game.

But then again, you are a perfectionist, and you dare not leave the wood sanding task to another. You must, by all means, achieve the perfect refined finish on your woodwork project. You know the benefits of quality wood sanding in enhancing the appearance of your woodwork, and so you are ready to put in the extra effort and time to reap maximum benefits.

Luckily, there are ideal tools you can use to make the not-so-fun, time-consuming task quick, easy and fun.

Enter electric sanders; orbital and sheet sanders

Differences between orbital sanders and sheet sanders

Although there are other wood sander types, orbital sanders and sheet sanders are the commonly used wood sanders. Each comes with a specialised purpose, although sometimes these purposes may overlap, and one wood sander may perform a similar wood finishing work like the other. However, orbital sanders and sheet sanders differ in the shape of the sanding surface, the abrasive used, application, cost, versatility, scratch pattern, and motion.

Motion

Sheet sanders mostly move back and forth in a straight line, with minimal side to side movements (linear motion), and at high speeds.

Orbital sanders have a sanding disc that moves in a random circular motion like its orbiting around the central point.

Application

Sheet sanders efficiently get in edges and corners, although they can cause grooves as they only move in one direction. It is also ideal for small surfaces and detail work.

Orbital sanders, on the other hand, are ideal for wide and open spaces. They don’t get inside corners properly. They are efficient for use on large-area pieces like cabinets and rougher materials. They are also perfect for projects where sheet sanders may be too passive or rough.

Other features

Orbital sanders have holes in the pad for sanding dust removal. Sheet sanders lack this dust collection port.

Abrasive

Sheet sanders mostly use ¼ -½ sheet of rectangular sandpaper held by two clamps in place.

Orbital sanders use round-shaped sanding disks that are held in place with velcro.

Cost

Sheet sanders are inexpensive, and sandpaper is also affordable for the models that use normal sandpapers. It is, however, more costly for models that use hook-and-loop sanding instruments.

Orbital sanders cost relatively more than sheet sanders with the same or different specs. The sanding disks are also more expensive than the regular sandpaper used in sheet sanders.

Scratch pattern

Sheet sanders only have some random oscillation and can leave some visible scratch patterns.

Orbital sanders typically oscillate and rotate to produce a scratch pattern that is not easily noticeable.

Versatility

Orbital sanders can do more work than sheet sanders. They can polish your woodwork to almost the same finish like a fine finishing sander.

Ease of use

Orbital sanders require one hand to operate, while sheet sanders require the input of both hands to use.

Pros and Cons of Orbital Sanders and Sheet Sanders

Orbital sanders

Pros

- Strong motor: it requires a stronger motor than a sheet sander because it should randomise the sanding pad motion. This extra power makes an orbital sander ideal for removing material.

- Dust collection mechanism: it ensures your workplace remains clean

- Versatility: it can be used for a wide range of work. Its high power output enables you to make good use of the spot.

- Speed: the sander comes with an additional feature of variable speed control, allowing you to choose the speed you require depending on the project you are working on.

- Finishing: because of the high power it holds compared to sheet sanders, it will not leave visible marks on your piece.

- Reduced fatigue: if you opt for a model with an anti-vibration mechanism, you will not suffer from fatigue and numbness.

- No swirl marks: using the sander in a random circular motion inhibits the tool from leaving visible marks on your woodwork pieces.

Cons

- Because of the vibration it produces, your hands may suffer from hand fatigue and numbness. To minimise this effect, you can opt for models with anti-vibration mechanisms or use an anti-vibration glove. The downside to these solutions for the vibration is that they are extra expenses. To be on the safe side, you can take frequent breaks to give your hands time to relax.

- Cost: its extra features and power make the product relatively more expensive than sheet sanders. The sanding disks it uses are also costly.

- Aggressiveness: it is more aggressive than sheet sanders, and if you are not careful, it may damage some materials

- You cannot use it on layered woodwork projects

- You also cannot use it for corners because of its round sanding disc.

Sheet sanders

Pros

- Affordability: it is less expensive than other wood sanders, and the regular sandpaper it uses is also inexpensive. This means both its initial and recurring costs are relatively low.

- Ease of use: this sander requires little practice before use and enables you to do a variety of jobs

- Availability: the sheet sander and the sandpaper to use are available almost everywhere

- Lightweight: this sander does not make you tire quickly because of its weight. This also makes it portable.

- It is ideal for doing detail work and finishing touches and can also be used to smooth between paint layers and coating.

Cons

- Versatility: it works on areas that other sanders cannot work on, like corners

- Scratch pattern: the sanding pad can leave marks on your piece because of the sander’s steady motion if you are not careful

- Low power output: it is not designed to work on large surfaces and heavy-duty tasks

Wood Sanders Review

Sheet sanders

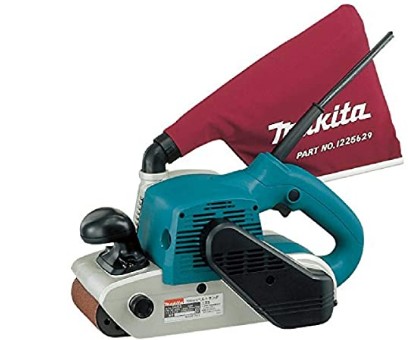

Makita 9403 belt sander

Features

- 4” wide belt that has a 1640 ft/min speed

- Labyrinth construction

- 4” x 24” dust bag

- Sound of 84dB

- 1-year warranty

Pros

- At 84dB, it’s the quietest in its class of belt sanders

- Its labyrinth constructions help seal the motor and bearings, protecting them from contamination and ensuring the tool lasts long

- Its wide belt and speed allow fast removal of material, making the sander efficient

- The sizeable front grip position is convenient and provides you comfort as you operate

- Its light, weighing 13pounds

- Ideal for carpenters, woodworkers, floor installers, furniture makers and contractors who require a quality belt sander or makeshift belt grinder.

- For grit control and convenient operation, it has a dustpan that swivels 360°

Cons

- It is expensive because of all the high-end features it has been installed

2. Astro

Features

- It has three sizes of sanding belt grit

- 360° adjustable arm

- Its engine produces 0.5hp, making it the industry’s leader

Pros

- It is ideal for spot weld removal, metal prep as well as cleaning welds.

- Its belt is simple and has a tension lever

- It has a speed control that allows you to fine-tune the speed to the one you require for operation

- It has increased pulley space that allows installation of thicker belts

Cons

- It is expensive

Orbital sanders

Bosch ROS20VSC palm sander

Features

- Smooth finish that eliminates swirl marks on your piece

- Hook-and-loop disc attachment system

- 2.5amp motor

- Microfilter system

Pros

- Its powerful motor allows you to find the right speed for you to work on your piece with ease through its variable speed control feature

- Its dust collection system ensures your operation is free of dust, which is favourable for your nose and piece as well

- Its soft-grip top and overall body design allows you to have multiple grip position

Cons

- The price may be pretty high for small woodworking businesses

Skil 5″ random orbital sander

Features

- 2.8 amp motor

- X-flow dust collection system

- On/off switch system

Pros

- With 13,000 opm (orbits per minute), it offers a smooth operation for your task, and its variable speed control allows you to choose the right speed for your task

- Its low vibration reduces hand fatigue

- It can get into tight spaces quickly and sand them

- The on and off switch makes it easy to switch the tool on or off during operation

- It does not leave swirl marks on your piece

- Ideal for metal, plastic and wood

Cons

- It may not be budget-friendly

When to use electric sanders

If you are a woodworker, you know there is a time for sanding by hand and when you require a tool. Sanding by hand is done on small and sensitive pieces that powered wood sanders can damage.

For large projects, however, you will need a powered wood sander because of its efficiency. It is advisable to use electric sanders when making furniture, cabinets, and staircases or stripping paint, to mention a few.

Is an Orbital Sander better than a Sheet Sander

In terms of application, an orbital sander is better than a sheet sander because it offers more work options compared to a sheet sander whose work is doing finishing touches and some detail work. Also, it can only be used on small pieces, while an orbital sander can be used on large pieces.

However, in terms of price, the sheet sander is better as it is relatively cheaper than the orbital sander.

Should I get a sheet sander or an orbital sander

Because of its versatility, an orbital sander is a perfect tool for a woodworker who wants to buy just one wood sander.

Are sheet sanders more expensive than orbital sanders

The supplementary requirements needed to build an orbital sander make it more costly than a sheet sander.

Conclusion

If you want the perfect finish and a versatile tool, you should get a random orbital sander. This tool is, however, more expensive than its sheet counterpart.

Alternatively, you can get both sanders if your budget allows it and if you want to be considered a professional because each is used for a specific purpose. However, if you cannot afford both, go for the orbital sander.

Lastly, not everyone has experience using these electric tools. It is necessary to provide training or supervision for beginners.