Single Stage vs Two Stage Air compressor

An air compressor is indispensable in any workshop providing a wide range of applications. The compressors come in different types, shapes, and sizes; they group in terms of CFM output, tank size, horsepower, and more. The standard type is the reciprocating air compressor, also called the piston. In this type, there exist two groups of compressors; single-stage and two-stage. In this article, we will discuss and differences between a single-stage and double-stage.

Differences Between Single-Stage and Two-Stage

The critical difference between the two compressors is how many times air gets compressed between the inlets valve and tool nozzle. In single-stage, the air compress one time, and in two-stage, the air compresses twice for double the pressure.

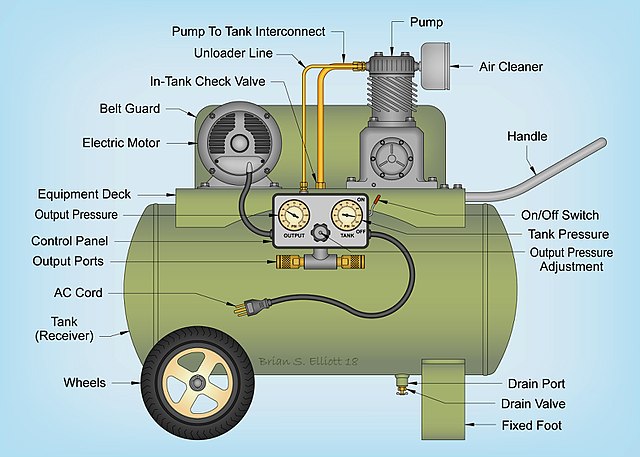

Single Stage Compressor Operation

In single single-stage, the process of taking up air is as follows;

- Air sucked into the cylinder.

- Trapped air compresses in a single stroke with a piston at 120 PSI.

- Compressed air moves onward to a storage tank.

- In the tank, the compressed air serves as an energy assortment for the tools dependent on this compressor’s power.

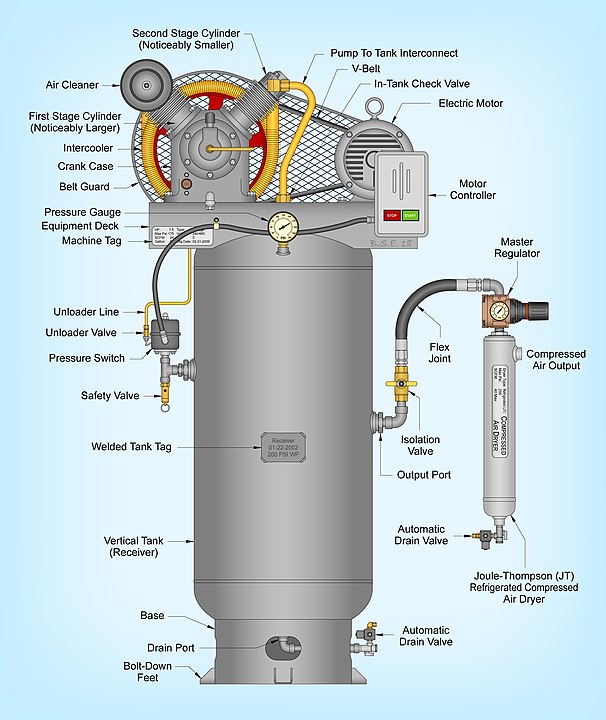

Double Stage Air Compressor Operation

In the double-stage, the processes are similar but vary a bit. The compressed air goes into a smaller piston for a second stroke instead of a storage tank at 175 PSI. The double pressurized air cools and goes to the storage tank, where it serves as energy for anything from high-powered equipment to pressurizing car tires or paintball gun tanks.

The Number and Shape of Cylinders

Another difference is in the number and shape of cylinders. Both compressors have cylinders, which are essential for balancing air. In single-stage, the piston has the same physical dimensions and the cylinder too. But in two-stage, it has one large piston for the first compression and a smaller one for the second compression. The difference in piston’s size makes one cylinder larger than the other.

Energy Consumption and CFM Output

Additionally, there is a difference in energy and CFM requirements. Single-stage compressors require less energy to run, unlike the two-stage, which needs more. The double-stage models are suitable for large applications that require a high energy supply.

Size and Portability

Single-stage is a small unit that you can easily transport from one room to another making it a perfect home garage compressor. But the double is more extensive and more massive, thus not portable. In terms of cost, the two-stage is usually more costly than a single -stage. The high price is due to components that make up the two-stage.

Single-Stage Pros

- The compressor has low costs of investments at the initial stage.

- It has a wide range of horsepower sizes from 3-600.

- It contains multiple options such as tank mount, integral dryer, and more.

- It gives you several different drives and, thus, flexible.

- It’s portable, and you can easily carry it for domestic applications.

- Easy to clean and maintain

- Best machine to deliver low air pressure

- Readily available in an oil-less form that saves you money

Cons

- There is no practical way to eliminate extra heat from the air compressor.

- It’s less durable.

- It has low efficiency.

- There is limited usage since it provides less PSI.

Two-Stage Pros

- It’s very efficient and runs without the off cycle.

- It helps you supply the required flow of energy with less horsepower.

- Has a longer lifespan due o minimal wear and tear.

- It allows you to work on heavy-duty tasks due to high pressure.

- It has a low-cost lifecycle, thus saves you money.

- Works smoothly without producing excess heat.

- Useful in gas and liquid industries due to its ability to compress elements of high molecular density.

Cons

- Has limited horsepower range 125 PSI plus.

- The initial purchase price is costly.

- It has fewer mounting options.

- It’s large and bulky.

- It requires high maintenance and proper care.

What is Better: Two-Stage or Single-Stage Air Compressor?

Whichever type of air compressor you choose it depends on several factors;

- Cost of the compressor

- Efficiency

- Applications

- Pressure output

- Portability

These factors and more dictate what type of air compressor you are going to purchase. The single-stage has one cylinder and one piston stroke for each revolution, thus less noise. The quietness makes it suitable for small working environments like workshops, garages. It also favors low CFM and PSI tools, and it’s portable. But as a drawback, it produces more heat, so it affects the operation in a small space.

On the other hand, the two-stage deals with heavy equipment in industries and has fewer maintenance costs. The best compressor depends on the above factors and your ability to purchase, especially for the dual-stage and its applications. For example, you wouldn’t buy a double stage to use it for part-time domestic tasks (running one nail gun or pneumatic sander at a go) unless it’s a business and you run multiple high volume tools at a go.

Is a Two-Stage[UU1] Compressor Worth it?

Suppose you don’t mind the higher up-front cost of a two-stage compressor; it’s worth investing in one. Well, if you need the extra punch, then it is worth it. If you don’t, the compressor’s bigger tank and higher pressure will keep your tools supplied for longer without turning on the engine to repressurize meaning that it will be a mostly quiet air compressor when you use it.

Conclusion

If you’re anxious about an air compressor to run tools in your garage, single-stage may be the best choice. Its power output is enough to run power tools and requires less space. But if running a factory that needs a lot of compressed air, a two-stage is the best fit and produces more compressed air. Even though it’s expensive, it’s worth the price.